50% OFF! Hot items selling fast—Grab them before they're gone!

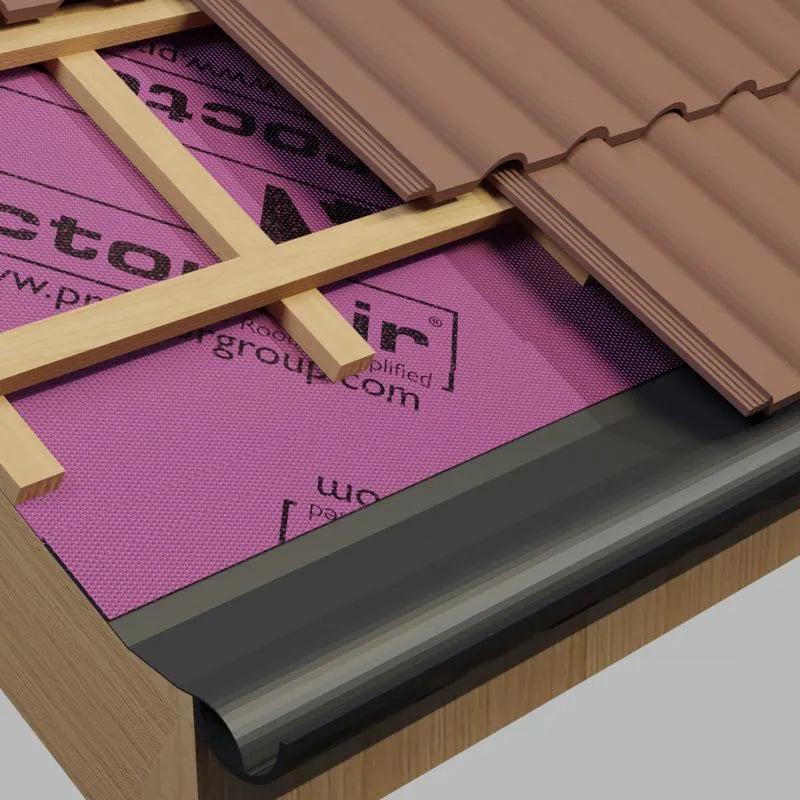

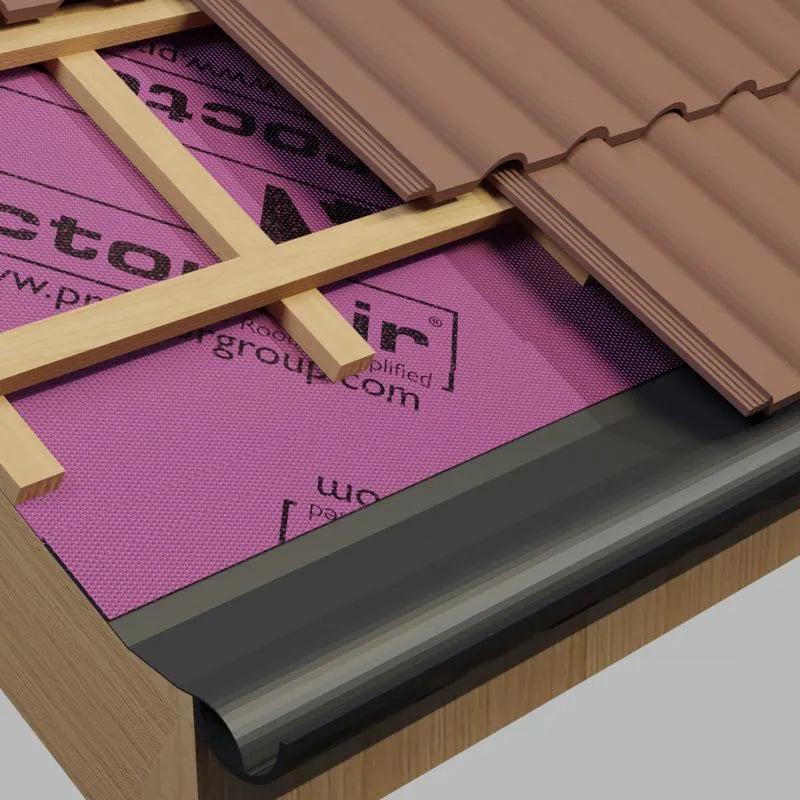

Proctor Air is a high-quality air and vapour-permeable breather membrane for pitched roofs, specially developed to provide excellent airflow and moisture management in this application.

Boasting an Sd-value of 0.02m and vapour resistance of 0.1 MNs/g, it provides a trusted, high-spec solution for effective ventilation and condensation control.

Proctor Air is designed to reduce the accumulation of moisture and effectively manage airflow while permitting the passage of excess vapour through the roof construction. This makes it especially suitable for use in high-moisture content areas, such as when drying out a newly constructed building.

Proctor Air has undergone extensive third-party testing to achieve and surpass BS5534 wind uplift performance in all UK wind zones, providing high performance without requiring additional tape.

Its unique air-permeable design provides enhanced airflow beyond conventional BS5250-compliant membranes, eliminating the need for costly ventilation equipment.

With effective installation and improved building performance, Proctor Air is the most suitable option for pitched roof installation, offering high standards of protection, durability, and adherence to industry-leading standards

1. What is Proctor Air VPU Membrane?

Proctor Air VPU Membrane is a high-performance vapour and air-permeable underlay designed for pitched roofs. It helps prevent condensation while allowing moisture to escape, improving ventilation and maintaining long-term building integrity.

2. How does Proctor Air VPU Membrane prevent condensation?

Unlike conventional underlays, Proctor Air VPU Membrane allows both vapour diffusion and air permeability, reducing condensation risks by enabling moisture to escape naturally. This makes it particularly effective during the drying-out phase of a building.

3. Is Proctor Air VPU Membrane suitable for non-ventilated roof constructions?

Yes, Proctor Air VPU Membrane is engineered for non-ventilated cold and warm pitched roof constructions. It eliminates the need for additional ventilation systems, saving costs on installation while ensuring superior moisture control.

4. What are the key technical specifications of Proctor Air VPU Membrane?

5. Can Proctor Air VPU Membrane be exposed to the elements during construction?

Yes, Proctor Air VPU Membrane is designed with hydrophobic properties in all three layers, allowing for temporary weather protection for up to four months during construction. However, it is recommended to cover it as soon as possible to maximize durability.

6. Does Proctor Air VPU Membrane require a vapour control layer (VCL)?

No, a vapour control layer (VCL) is not required when using Proctor Air VPU Membrane in non-ventilated cold pitched roof applications. Its superior vapour permeability allows moisture to escape without the need for additional layers.

7. How does Proctor Air VPU Membrane compare to traditional breathable membranes?

Unlike traditional vapour-permeable membranes, which are often airtight, Proctor Air VPU Membrane offers both vapour and air permeability. This unique feature provides enhanced airflow, reducing condensation risks without the need for mechanical ventilation.

8. Is Proctor Air VPU Membrane compliant with UK building regulations?

Yes, Proctor Air VPU Membrane meets key UK building standards, including:

9. Can Proctor Air VPU Membrane be used with different roofing materials?

Yes, Proctor Air VPU Membrane is compatible with various roofing materials, including:

10. Where can I buy Proctor Air VPU Membrane?

Proctor Air VPU Membrane is available through us! Order online today.